Food Maker Used Batch Processing to Boost Quality by 30%

A large global-brand snack baker suffered excessive production losses and inferior financials at one plant for far too long. Low yield, poor dough quality and unplanned downtime all were created by the problematic batch control system for its 12 mixing stations and ingredient delivery systems.

To complicate things, the existing code was inaccessible and “locked-down” as a precaution of the proprietary software. Frustration mounted daily as everyone knew what the problem was, but recognized the implications of untangling it while maintaining the business’ pace. Undue stress, worry and weak performance eventually brought management to its knees.

Do Nothing or Do Something?

They seemed to have only two options. One, do nothing and continue to suffer the ills of the aging system, poor production, inefficiency “tax” and lack of flexibility to upgrade. Two, shut down each of the 12 mixing stations one by one over a long and drawn-out transition period, replacing and testing code in each of the 14 individual programmable automation controllers (PACs) and hope, after several months of change, that production for the entire plant would improve.

The Third Option

But what if there were a third option? What if all the code for the 14 PACs, all the human-machine interface (HMI) stations and a new batch management solution could be written and tested on a running system — offline?

This could shorten downtime significantly, create confidence in the new code and reduce the risks to the business. This would mitigate unpredictable results, escalating costs and an indefinite shutdown.

The snack company asked Rockwell Automation System Integrator Gold Partner Polytron to emulate the mixing systems before installation to operate them virtually and try “what-if” situations. This gave the manufacturer confidence in the new batch management and control system so the company could shut down the entire mixing area — effectively, the entire plant.

The company then could replace all of the mixing station and ingredient delivery system programming knowing production would start back up just a few days later.

Unlocking the Code: A New Approach

The existing batch control system had been installed several years earlier and contained locked-down, proprietary code that still had bugs; the plant couldn’t support or modify the system on its own. The snack baker had to rely on a supplier who was tough to schedule, was hundreds of miles away and came at a high cost.

This snack maker required an open, standard approach to provide the ability to operate and maintain its own systems with its own staff.

Replacing locked code presented its own challenges:

- With no documentation for the existing system, Polytron and the snack baker had to redefine how the system was operating and reverse engineer all the code before starting on the new code.

- The system integrator’s team of engineers and the plant’s batching systems experts worked side by side, tapping into the operations supervisors’ expertise and knowledge to verify the appropriate technology transfer was applied so the new code definition captured critical information.

- Creating a detailed description of how the new FactoryTalk® Batch system from Rockwell Automation would operate was essential to making sure the snack baker wouldn’t lose time retraining its operators on a completely new system.

- Using the detailed description, the existing ControlLogix® processors were reprogrammed using PlantPAx

were reprogrammed using PlantPAx® Library of Objects for standardization of code.

- The FactoryTalk View HMI screens had to look and operate the same. To accomplish this, existing HMIs were replaced with thin clients using ACP ThinManager and FactoryTalk View. Sequences had to work just as they did previously. And all the batch recipes had to be followed precisely to meet strict food quality standards.

- The existing Windows PCs in the facility were replaced with thin clients using ACP ThinManager.

- Integration with each of the subsystems had to be rewritten to flawlessly integrate each critical system into the entire solution.

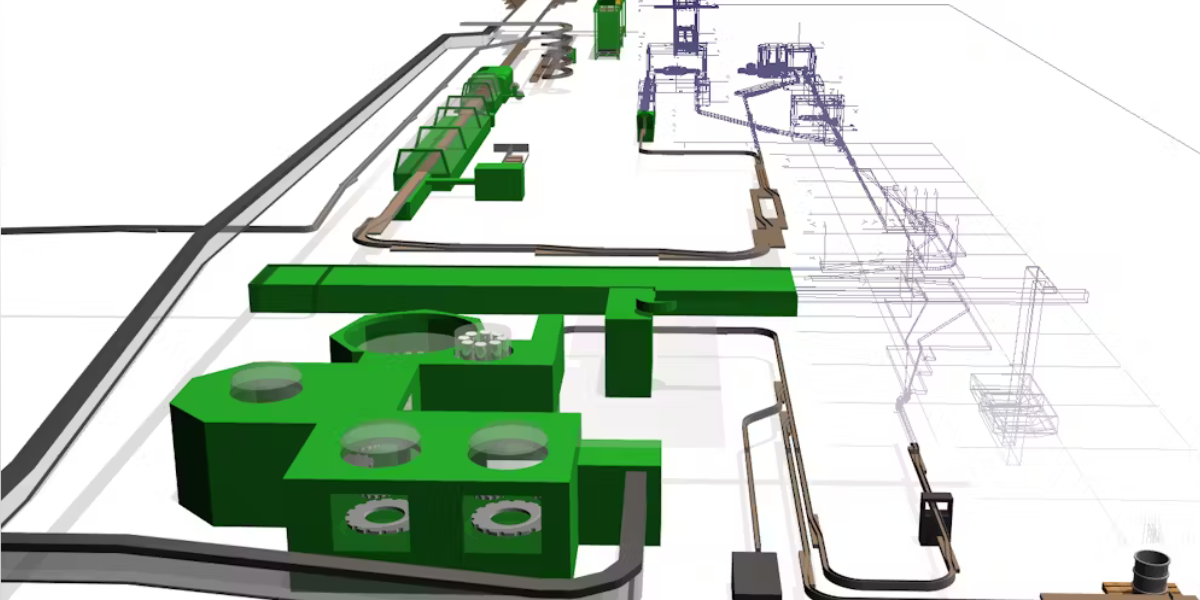

Another Polytron team created a simulation model of the plant’s entire mixing system: 12 mix stations and almost two dozen dry and liquid ingredient delivery subsystems. All in all, more than 700 devices were modeled. When connected to the PACs, HMIs and new batch management solution, the baking company had a fully operational batch system that could be tested offline.

Polytron used simulation software with PlantPAx to simulate IO drivers using EtherNet/IP™ and OPC specifically made for the Rockwell Automation Logix and Studio 5000 Logix Emulate™ automation platforms. The team could test the new control system with a dynamic, realistic simulation of their plant.

The team spent days verifying recipes and operating scenarios, manual and automated sequences and even potential faults and recovery steps. After participating in some of this extensive testing, the plant manager felt confident in shutting down the plant with little risk of missing the start production date.

Moment of Truth

Will it work without hitch or glitch on Monday morning? That was the question and the buzz around the plant. The baking company extended its already planned Thanksgiving shutdown by just one day. Polytron had to deliver and have the plant back in production Monday morning.

The planning, modeling and testing paid off. According to a representative from the baking company, “The ability to run a full precheck was invaluable and eliminated the guess work and uncertainty at start-up. The new code was introduced into the system in a seamless fashion, which resulted in an on-time start-up.”

By nine o’clock Monday morning, only five days later, all the systems had been cleaned, and new dough was flowing.

The Real Payoff

The completely new batch management and control solution met all expectations: no unplanned downtime, technicians now had access to examine code at will, and quality specifications were on target.

Even better, downtime decreased by 25% and dough quality improved 30%, meaning no bad batches.

Operators were up and running in no time. One even asked a week after the programs had been switched, “So, when are we going to make the changes to the system?”

This article was published by the Rockwell Journal and has been shared from its original source.