Chris Parkinson is HMI technical lead at Polytron, a CSIA-certified member of the Control System Integrators Association (CSIA). Below is a Q&A with Chris conducted by Mike Bacidore, chief editor of Control Design.

What have been the biggest improvements to operator-interface technology in the past five years?

Portable devices like smart phones and tablets as well as wearables bring information to the manufacturing users who many times are not sitting at their desks or in front of an operator-interface terminal (OIT) but are in other areas of the plant. We are seeing many applications that leverage these technologies.

Serving up digital-workflow instructions to smart phones, tablets and wearables has brought information normally available on a stationary OIT directly to the user who is working to troubleshoot an issue, assemble a product or perform other standard work instructions.

Also read: HMIs create a window of opportunity

What’s the most innovative or efficient operator-interface technology application you’ve ever seen or been involved with?

A line-based supervisory-control-and-data-acquisition (SCADA) system provides detailed performance via tracking rejects in a highly automated medical device assembly plant. The SCADA system is installed at a level above the 12-14 work-cell human-machine interfaces (HMIs) and provides a unified, granular view of how the entire line is performing as a whole.

How has operator-interface technology benefitted from remote monitoring and connectivity?

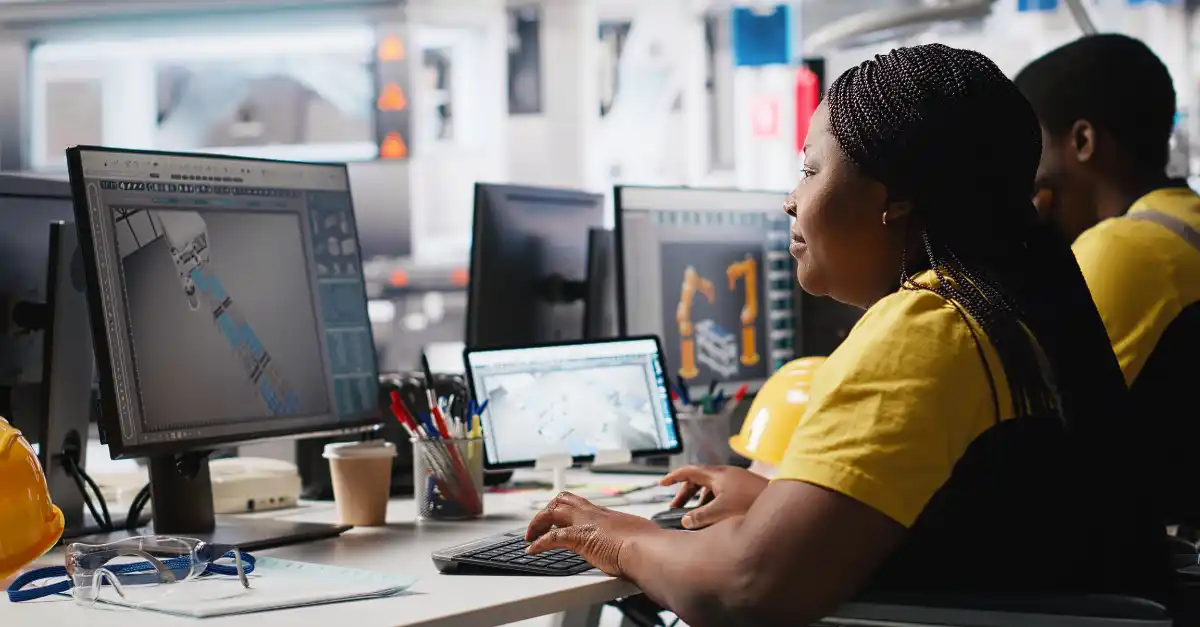

Figure 1: Large manufacturing facilities benefit from a central control station where the maintenance personnel can monitor multiple departments or the entire plant at one time.

Central monitoring stations, either inside the plant or remote, are becoming more popular. Large manufacturing facilities benefit from a central control station where the maintenance personnel can monitor multiple departments or the entire plant at one time (Figure 1).

Also read: Membrane puts the human in HMI

Smaller and medium-sized manufacturers can also benefit from this concept but using a remote control room that is monitored by a third party. This third party can be a corporation monitoring multiple facilities or a vendor outside the company that provides these types of services.

Thin-client technologies provide a means to combine information from many sources and present it coherently. Shadowing functions built into thin clients allow troubleshooters to see what an operator is seeing at a specific location.

How do operator-interface technologies figure into digital-twin platform models being used by manufacturers?

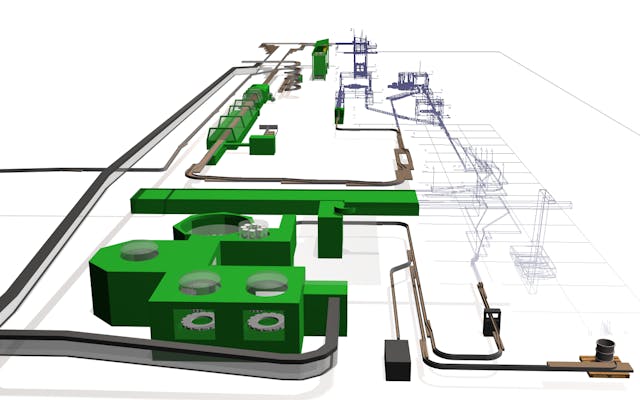

For pre-startup simulations, operator-interface technologies provide an opportunity for the operators and technicians to see what will be installed and provide feedback prior to installation (Figure 2). This reduces downtime and leads to faster startups.

Figure 2: Operator-interface technologies provide an opportunity for the operators and technicians to see what will be installed and provide feedback prior to installation

As a training tool, the technologies provide plant personnel with a safe place to try different scenarios, refresh training and bring new folks up to speed.

When will operator interfaces become IT-friendly enough that engineers are no longer required for installation and operation?

It is not just a question of IT-friendliness. Operator-interface development often involves interpreting complex technical concepts and presenting them in a way that is easy to understand. This requires understanding how people comprehend and process information. It requires experience in automation systems so that nuisance data is suppressed and relevant data is transformed into actionable information.

Also read: Safety standards, regulations and requirements protect humans and machines

What future innovations will impact the use of operator-interface technology in manufacturing operations?

Wearable technologies, specifically smart glasses that bring information to the individual where they are at any moment, and augmented reality, with the ability to add information to what an individual is experiencing, will impact the use of OI

This article was published by Smart Industry and has been shared from its original source.

.png)